Pressed Steel Sectional HDG Water Tank

Galvanized pressed steel water tank is also called a pressed steel sectional water tank, galvanised water tank, pressed steel water tank, rectangular steel water tank, and galvanized steel water storage tanks. It belongs to a new type of water tank. It is made of hydraulically pressed panels.

HDG water tank is the short of Hot Dip Galvanized water tank, with 90 μm thick surface zinc coating of Q235 Pressed Steel. Zinc coating can help to prevent rust and corrosion over at least 10 years. HDG water tanks have the most panel types including 1000 × 1000 mm, 1000 × 500 mm, 500 × 500 mm, 1220 × 1220 mm. So HDG water tanks are more flexible and high cost-effective. Meanwhile, the strong steel structure and zinc coating protection has made it available to be used as underground water tanks.

Pressed Steel Sectional Rectangular tanks provide a convenient means for the bulk storage of liquids. And over the years, one name has earned a reputation that’s strong as steel for being the reliable choice: HDG. That’s because HDG Pressed Steel Tanks are manufactured to the highest level of quality, and conform to the British Standards BS 1564:1975 and Amendments and BS 729:1971 (for hot-dip galvanizing service).

Features

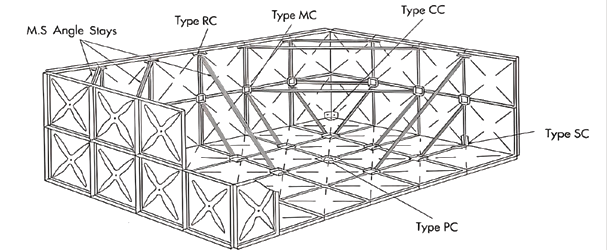

- The tanks are bolted together, complete rigidity is ensured by angle stays fixed to cleats which are bolted onto the tank plates.

- Its seams are sealed with a jointing compound which is non-toxic and does not impart any taste to the water.

- The internal and external surfaces of tank plates, stays and cleats are painted with a non-toxic and non-contaminating block bituminous paint.

They can be built in awkward locations unsuitable for other forms of construction. They can be built in “L” or “U” shape and can be portioned into two or more compartments as required. We have many galvanized & metal steel water tanks for sale such as panel water storage tank, mild steel water tank, steel potable water storage tanks, stainless steel drinking water tanks, corrugated metal water storage tanks, especially, 20000 gallon steel water tank. Many of our customers use the pressed steel tank, because of the tank panel that is lightweight and portable.

We give a reasonable price according to the customer’s needs, especially, 5000 gallon steel water tank price. Many of our customers have bought 5000 gallon steel water tanks for homes from us.

General Specification

■ Standard – Pressed steel sectional HDG water tank constructed with hydraulically pressed flanged panels, conform to BS 1564: 1975 and SS22:1979.

■ Materials – The steel used in the manufacture of the tank plates, stays and cleats conform to the requirements of BS 4360: 1972 grade 43A or ISO equivalent.

■ Flanges of Plates – Tank plates are pressed with a combined double flange at an angle of 45 degree and 90 degree to the face of the plate on four sides.

■ Stays and Cleats – The stays and cleats are made of steel angle bar and steel plate

■ Bolts, Nuts and Washers – Hot Dipped Galvanised steel bolts, nuts and washers for internal and external.

■ Jointing Materials – Non toxic PVC foam sealent tape for all jointing between tank panel flange.

■ Tank Cover – Panel type steel cover supported by trusses 600 × 600 square manhole and 100mm air-vent supplied as standard for each compartment.

■ Water Level Indicator – Transparent acrylic tube with aluminium casing and height level marking or mechanical ball float type.

■ Nozzles for Connection – Short pipe with flange or socket for all pipe connections.

■ Ladder – Aluminium or HDG Steel ladder for internal and external access.

■ Finish – Hot Dip Galvanised conform to ISO 1461.

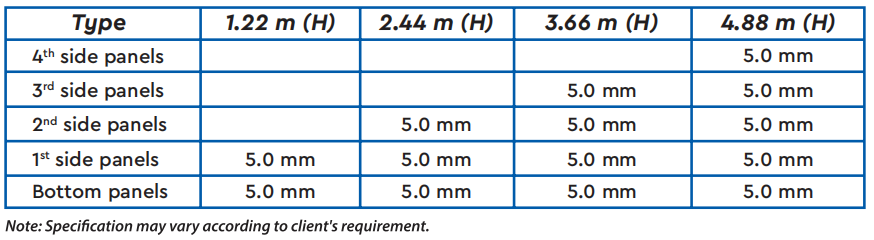

STANDARD THICKNESS FOR

1.22 m X 1.22 m TANK PANEL

STANDARD THICKNESS FOR

1.0 m X 1.0 m TANK PANEL